Decapping machine for Covid-19

A flexible de-capping solution for different sizes

of test tube caps used for SARS-CoV-2 diagnostics.

Covid-19 test tube decapper

To receive CAD drawings and Bom list send an e-mail to lars@kompositmekanik.se

Opensource attribution - You must give appropriate credit, provide a link

to the license, and indicate if changes were made. You may do so in any

reasonable manner, but not in any way that suggests the licensor endorses

you or your use.

Link to video:

Test tube decapping machine

This is a collaboration between Karolinska Institute and

KTH Prototype Center

Background

Opening many test tubes is both a time-consuming and laborious task. Unfortunately,

the procedure of removing the cap (de-capping) from the tube must often

be carried out manually as there are no or few automatic solutions capable

of handling a large variety of test tubes.

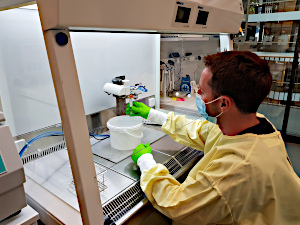

Benjamin Heller Sahlgren have been involved in starting the COVID-19 diagnostics

pipeline at the Karolinska Institute, where he and a fellow college has

been responsible for starting and administrating the sample reception

unit. Considering that the sample reception laboratory is the first step

in the diagnostics pipeline and thus directly handles the incoming samples,

the unit quickly identified the need for a automatic solution capable

of removing the burden of the manual de-capping step.

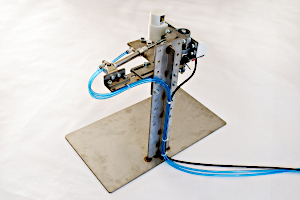

Since the incoming test tubes differed both in size and diameter, an automatic

de-capping solution capable of handling a large variety of tubes was required.

However, such a machine was not available on the market and thus the potential

of building a novel de-capping machine became the only feasible solution

to the problem. KTH Prototype Center was contacted, and the situation

and the requirements were explained to Lars Hässler who immediately

started the development of a novel de-capping solution. The result was

a machine flexible enough to remove almost all kinds of caps that differ

not only in size and diameter but also design.

Machine designe

Lars Hässler larhas@kth.se / lars@kompositmekanik.se

www.kthprototypecenter.com/ / www.kompositmekanik.se/

Covid-19 testing

Benjamin Heller Sahlgren: benjamin.heller.sahlgren@ki.se

https://ki.se/en/mbb/ulf-eriksson-group

In the BOM list, you can find everything about materials

and manufacturing for a test tube opening machine.

Photo / film Lars Hässler and Benjamin Heller Sahlgren

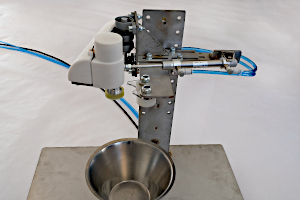

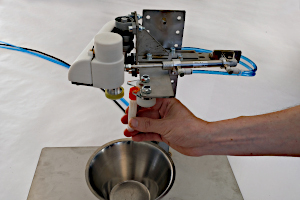

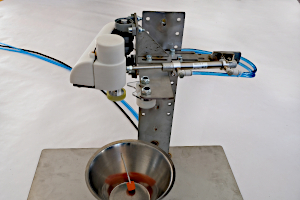

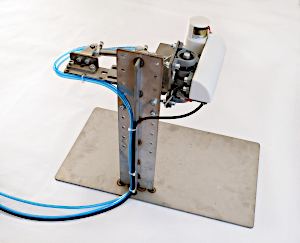

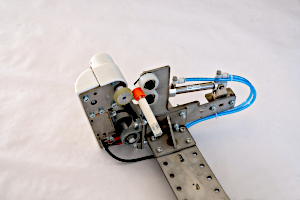

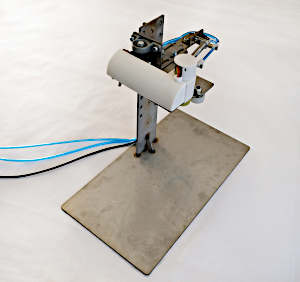

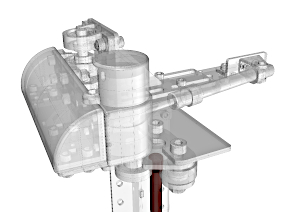

(Fig. 2) Insert the test tube between the two non-drive rollers

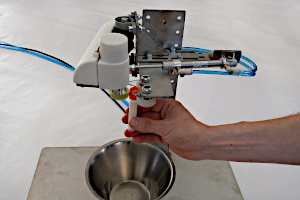

(Fig. 3) Press down the foot pedal, the arm with the motor and the drive

roller

move towards the test tube and the engine starts.

(Fig. 3) The cork is swirled from the test tube and the cork with swab

remains in place.

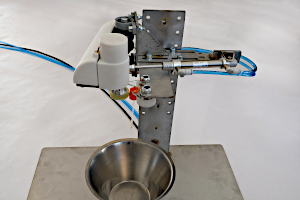

(Fig. 4) Remove the test tube without swab loosening and place it in

the test tube rack.

(Fig. 5) Release the foot pedal and the cork and swab falling into the

garbage container

and the machine goes to sleep / start position control:

The drive wheel pressure against the test tube is adjusted by raising

the pressure from the pressure regulator

(Fig. air pressure gauge)

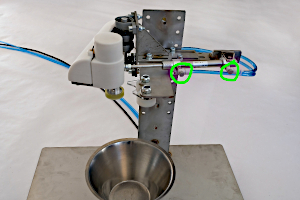

Arm speed in / out is controlled with the two small gray knobs (Fig.

6)

When the arm is in the open / rest position, the microswitch is pressed

and the motor receives no current.

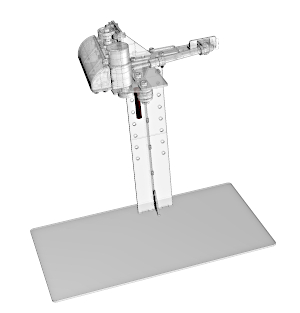

Some more illustrations

Collaboration between Karolinska

Institutet and KTH Prototype Center

www.kthprototypecenter.com

https://ki.se/en/mbb/ulf-eriksson-group